Ink Examinations

Materials Testing Department

The SID Testing Laboratory can carry out a variety of tests on the materials used in printing.

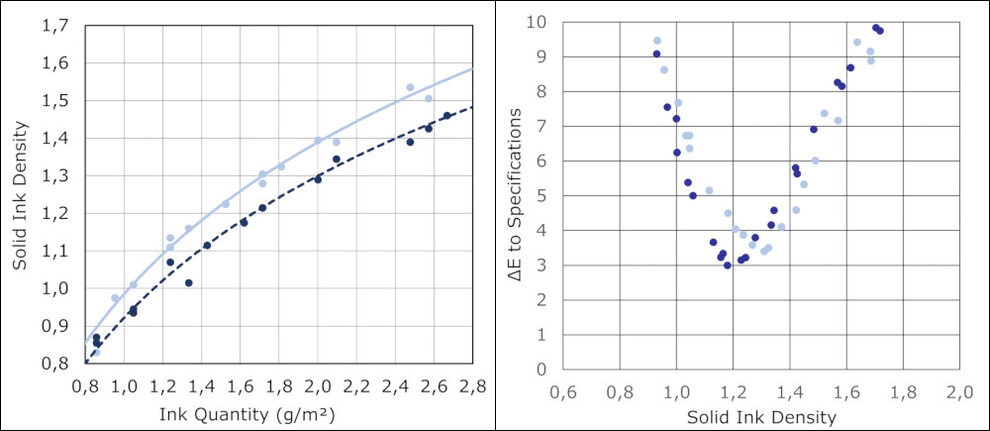

To assess the yield of printing inks, standardised print samples with gradually varying layer thicknesses are produced on the printabilty tester and the ink densities obtained are measured (Tollenaar curve). Using this, the amount of ink required to achieve a specified density or colour and thus the yield can be calculated. This property is critical for determining ink consumption in the printing process and therefore represents an important cost factor in production.

The sliding friction coefficient of the ink surface can be used to estimate the drying behaviour or the degree of curing of printing inks. The surface becomes smoother the drier/more cured the ink is. This relationship is well-known with UV inks and varnishes and is used by the UV Cure Check measuring device which is offered by PITSID GmbH to determine the degree of curing.

However, this method can also be used for other ink systems, e. g. for oxidative drying inks or for dispersion varnishes. As these inks take a relatively long time to completely dry, the coefficient of sliding friction is measured at fixed intervals and the time at which no change occurs is recorded. This final value can be used to calculate the drying progression over time.

Ink Examinations

Your contact partners:

Dipl.-Ing. Beatrix Genest

Tel: +49 341 25942-28

Dipl.-Ing. (FH) Carolin Sommerer

Tel: +49 341 25942-23